Water Supply in High Rise Building

Domestic Water Supply & Plumbing Installation In High Rise Building

Roof Top Tank

uCreated more than a century ago

uEnsure adequate water pressure in buildings

uThe alternative to roof tanks is the use of pressurised systems, where a number of booster pumps provide the necessary pressure.

uRequired water pressure for both fire-fighting and domestic use increased and mains water was insufficient to supply a whole building.

uReliable and efficient pumps for pressurised systems were not available.

uThe immediate solution was to use standard pumps to lift the water to the tank. From the tank, gravity ensured a natural downwards flow and sufficient pressure.

Disadvantage

üHigher capital costs due to the tank set-up and greater structural requirements

üHigh operating costs

üLack of pressure control

üDifficulty in maintaining the roof tank

üBecome the habitat of micro-organisms

Advantages

-Only one riser needed (simple design)

-No space required on upper floors

Disadvantages

-Excess pressure on lower floors in buildings exceed ten floors (PRVs and high pressure graded pipes needed)

Roof tank solutions

Roof tank solutions were originally created more than a century ago, as building grew taller and taller. The required water pressure for both fire-fighting and domestic use increased and mains water was insufficient to supply a whole building. Moreover, reliable and efficient pumps for pressurised systems were no available. The immediate solution was to use standard pumps yo lift the water to the tank.From the tank, gravity ensured a natural downwards flow and sufficient pressure. Despite improved and energy-efficient pressure booster technology, many buildings still have roof tanks.

Coupling

Pillar Tap

Pneumatic Tank System

The aim of the project is pneumatic operated water pumping system. Air compresses is used to compress air from a low inlet pressure (usually atmospheric) to a higher pressure level to allow water flow up to a higher floor. This system worked well if properly maintained. Due to high precision work involved in producing pneumatic water pump besides higher cost these pumps are not widely manufactured by most of the industries.

Advantages

üHigher pressure

üQuite running and smooth operation

üHigher efficiency

üLess maintenance

Disadvantages

üCostlier than the other types of pump because of compressor unit.

The two basic configurations for most water distribution systems are the

branch and grid/loop (see Figure). A branch system is similar to that

of a tree branch, in which smaller pipes branch off larger pipes

throughout the service area, such that the water can take only one

pathway from the source to the consumer. This type of system is most

frequently used in rural areas. A grid/looped system, which consists of

connected pipe loops throughout the area to be served, is the most

widely used configuration in large municipal areas. In this type of

system there are several pathways that the water can follow from the

source to the consumer. Looped systems provide a high degree of

reliability should a line break occur because the break can be isolated

with little impact on consumers outside the immediate area. Also, by

keeping water moving looping reduces some of the problems associated

with water stagnation, such as adverse reactions with the pipe walls,

and it increases fire-fighting capability. However, loops can be

dead-ends, especially in suburban areas like cul-de-sacs, and have

associated water quality problems. Most systems are a combination of

both looped and branched portions.

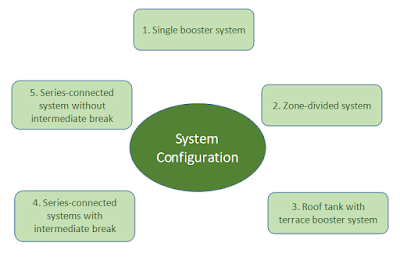

Single Booster System

The simplest way to achieve equal tap water pressure on all floors is by producing excessive pressure and then removing it again

Having just one booster set delivering water to the whole building leads to significant pressure differences in the system.The boosting station in the basement has the pumps power to overcome the pressure head loos of a system that reaches all the way to the top floor. But this also requires pressure relief valves to be installed in order to remove excessive pressure. In other words, not only do you need to invest in additional components, you're also removing the pressure you just spent energy on producing.

Having just one booster set delivering water to the whole building leads to significant pressure differences in the system.The boosting station in the basement has the pumps power to overcome the pressure head loos of a system that reaches all the way to the top floor. But this also requires pressure relief valves to be installed in order to remove excessive pressure. In other words, not only do you need to invest in additional components, you're also removing the pressure you just spent energy on producing.

A single booster system is perhaps the simplest booster system available. It relies on a single set of pumps supplying pressure boosting from the basement to the point farthest away from the booster system. Basically, such systems may be configured with or without initial break tanks.

Advantages

-Only one riser needed (simple design)

-No space required on upper floors

Disadvantages

-Excess pressure on lower floors in buildings exceed ten floors (PRVs and high pressure graded pipes needed)

Zone-Divided System

The intelligent way to boost water is to produce the pressure needed at each floor-no more, no less

By dividing a tall building into booster zones, you can define the flow and pressure needed at each zone.Sizing each booster to meet your exact demands in then an easy calculation in Grundfos Product Center. With each booster now pumping at the exact speed required, the effect on energy consumption is clear : there is no more energy waste from reducing overpressure and the pumps perform for the load profile of each zone. Our booster sets intelligently adapt to demand, eliminating the need for pressure relief valves - all while ensuring reliable and efficient operation at all times.

Advantages

-Manageable pressure zones

-Increased flexibility and security due to zoning

-No space required on upper floors

-Low-cost operation due to no residual pressure

Disadvantages

-Higher initial cost than single-zone systems

-Higher static pressure in upper zone (high-presssure graded pipes)

Roof Tank With Terrace Booster System

The use of roof tanks to ensure adequate water pressure in building and especially tall building is very common. The alternative to roof tanks is the use of pressurised systems, where a number of booster pumps provide the necessary pressure.

Roof tank solutions

Roof tank solutions were originally created more than a century ago, as building grew taller and taller. The required water pressure for both fire-fighting and domestic use increased and mains water was insufficient to supply a whole building. Moreover, reliable and efficient pumps for pressurised systems were no available. The immediate solution was to use standard pumps yo lift the water to the tank.From the tank, gravity ensured a natural downwards flow and sufficient pressure. Despite improved and energy-efficient pressure booster technology, many buildings still have roof tanks.

Series-connected system with intermediate break

Series-connected systems with intermediate break tanks draw on several other systems, utilizing centrally-placed break tanks to supply both the taps, the tank’s own boosting zone and all the zones above it. With this system, a building is divided into smaller and more manageable pressure zones. Every zone is then served by its own booster set.

Advantages

- Low pressure in each zone (no PRVs and less pressure-graded pipes needed)

- Manageable pressure zones

- Easy to size because each zone has its own supply tank

Disadvantages

- Higher initial cost than single-zone systems

- Space required for booster sets and tank on service floors

- Risk of Microbiological growth in tanks

A series-connected system operates on the same principles as the previously mentioned system, but without the intermediate break tanks. This enables an effective usage of power as the water is only pumped to the part of the zone where it is used and not past it. However, complete control is very important. When a consumer draws water on the upper floors, the booster systems must be able to deliver the water from the bottom of the building.

Advantages

- Low pressure in each zone (no PRVs and less pressure-graded pipes needed)

- Manageable pressure zones

- No space required for tanks

- Less excess boosting (low operation costs)

Disadvantages

- Higher initial cost than single-zone systems

- Space required for booster sets and tank on service floors

- Complex control

Valves and Fittings

Valves

A valve is a device that regulates, directs or controls the flow of water by opening, closing, or partially obstructing various passageways.With valves, the caring of water to equipment and appliances has to be capable of being shut off so that pipework and appliances can be repaired and maintained. There are several types of valves, but in this chapter only focus on 4 types of valves.

Stop valve

lUsed in plumbing applications to shut off flow of hot or cold water to a plumbing fixture, such as a faucet,toilet, dishwasher and similar.

lUsed to control water at high pressure.

lAllow to perform routine maintenance such as filter change and drain cleaning, as well as to replace the entire fixture or appliance or make minor repairs such as changing gaskets or water supply connectors.

Gate valve

nOpens by lifting a round or rectangular gate/wedge out of the path of the fluid

nUsed when minimum pressure loss and a free bore is needed

nOften used when a straight-line flow of fluid and minimum restriction is desired

Float/Ball valve

uAutomatic flow control devices fitted to cisterns to maintain an appropriate volume of water.

Scour valve

vScour valves are located at low points or between valved sections of the pipeline

vAllow periodic flushing of the lines to remove sediment and to allow the line to be drained for maintenance and repair work

Fitting

A fitting is used in pipe system to connect straight pipe or tubing sections, adapt to different sizes or shapes and for other purposes such as regulating (or measuring) fluid flow. Fittings especially the uncommon types require money, time, materials and tools to install and are an important part of piping and plumbing systems.

Elbow

²Elbows are industrial fittings that change the direction of piping

²Allow a regular threaded pipe to turn corner or fit in limited space without the expense of buying a pipe bender.

²Type:45,90 and 22.5 degree elbow

Coupling

uA very short length of pipe or tube with a socket at one or both ends that allowa two pipes to be joined together

uConnect the pipes of same diameter

uUseful if the pipe is broken or leakage occurs

Union

ØSmaller to a coupling

ØFunctions as similar to coupling.But coupling cannot be removed after fixing but in this case we can remove the union whenever we needed

ØAllows the convenient future disconnection of pipes for maintenance of fixture replacement

ØConsists of three parts: a nut, a female end and an male end

Reducer

vReduces the flow size from larger to smaller by reducing size of pipe

vAllows for a change in pipe size to meet hydraulic flow requirements of the system or adapt to existing piping of a different size

Tee

nUsed to combine or divide fluid flow

nCan connect pipes of different diameters or change the direction of a pipe run

nMay in equal or unequal size

Pillar Tap

lA tap with a vertical inlet pipe and free outlet

lSupply water to basin, bath, bidets and sink

Bib Tap

nUsed for wall fixing, normally about 150mm above a sanitary appliance.

No comments:

Post a Comment